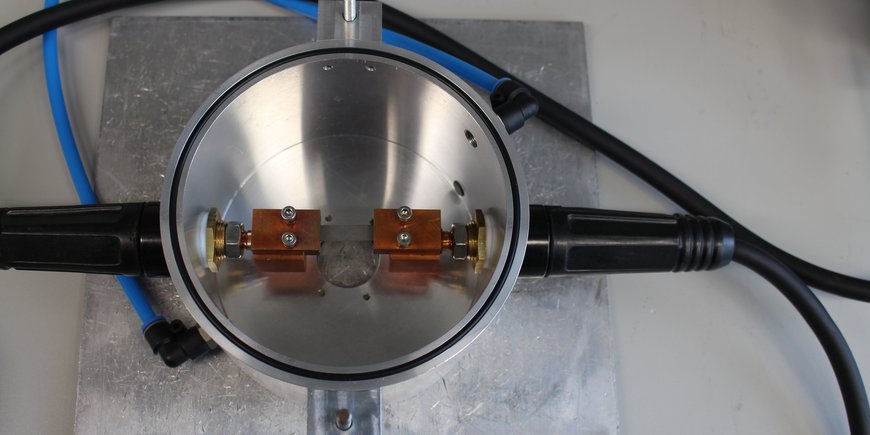

An iridium strip heater is a specialized heating device that uses iridium, which has a high melting point, corrosion resistance, and excellent electrical conductivity. At the HELGES laboratories, the Iridium strip heater is used to produce homogeneous glasses out of powder within a short time at a high-temperature impact. Within a few seconds, the carrier strip heats up to ~2000°C, thus heating the sample, and cools down again almost immediately to room temperature. This allows homogeneous melts to be produced with minimal loss of volatile components. The glasses then can be used for measuring both isotope ratios and element concentration by in-situ analysis techniques (such as laser ablation).

Beside Iridium, it is also possible to use a tungsten strip, but this can lead to discoloration in the melt. A sample quantity of around 40 mg is usually enough to produce a melt of sufficient thickness.

In addition to melting sample material, we have also had good experience with melting quartz grains as a standard and regularly use this for isotope analysis using laser ablation. Subsequent embedding in resin can also be carried out in our laboratories.