Storing heat underground can make an important contribution to the heat transition. One possibility for this is the storage of heat in aquifers, i.e. in permeable, groundwater-bearing rock layers (Aquifer Thermal Energy Storage (ATES)). A team from the GFZ German Research Centre for Geosciences from Section 4.3 “Geoenergy”, led by Dipl.-Ing. Stefan Kranz and Dr Katrin Kieling, is using a 410 metres deep research borehole to investigate whether a Jurassic sandstone layer (Hettang) at the Berlin-Adlershof site is suitable for an ATES system. This is to be implemented in the existing district heating network. The borehole was successfully completed in September. Further analyses are now taking place.

See on-site impressions of the project in the picture gallery above.

Background: Potential of underground heat storage in south-east Berlin

At the Berlin-Adlershof site, the “Berliner Blockheizkraftwerks-Träger- und Betreibergesellschaft” (BTB) is building Berlin's largest heat storage facility as part of the “Reallabor GeoSpeicher Berlin” project – in cooperation with the GFZ German Research Centre for Geosciences and TU Dresden. The aquifers envisaged as storage layers are located at a depth of around 400 metres with temperatures of around 23 degrees Celsius. Water at 90 degrees Celsius is to be injected here in summer. It stores the excess heat from a wood-fired power station, in which waste wood is used to generate energy. In winter, the hot water is pumped back up and fed into the existing district heating network. Modelling shows that around 85 per cent of the heat fed in can be recovered.

The planned aquifer storage facility is intended to contribute to the decarbonisation of district heating in south-east Berlin: it will enable a quarter of the heat that currently still comes from the Berlin-Schöneweide coal-fired power station in winter to be replaced by renewable energy. In this way, around 10,000 tonnes of CO2 can be avoided each year.

How the drilling was done

The drilling work took place from 29 July to 2 August 2024 as part of the EU-funded PUSH-IT project. A sidetrack was drilled from an existing borehole using the directional drilling method, i.e. a branch that leads away from the original borehole at a slight incline. The colleagues from the drilling company “Anger's Söhne Bohr- und Brunnenbaugesellschaft mbH” and from the Geoenergy Section of the GFZ worked together day and night in a 24-hour operation mode.

In order to obtain continuous information on the grain size distribution in the rock and the chemical and mineralogical composition from the drilling section between 211 and 410 metres deep, a sample of the drill cuttings was taken and examined for each metre of drilling. Some of the samples were characterised directly on site by geoscientist M.Sc. Lioba Virchow, who is doing her doctorate at the GFZ, using mobile X-ray fluorescence analysis.

Analyses of the deep rock

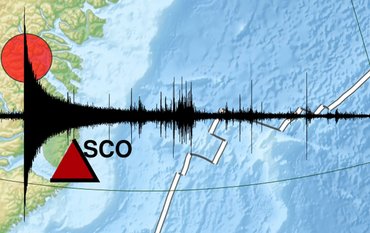

Once the drilling work had been successfully completed, various geophysical borehole measurements were carried out in order to further characterise the reservoir rock. The borehole was then completed: it was cased, whereby the casing in the area of the potential storage layer – between 371 and 389 metres deep – was designed as a filter to the rock. Fibre optic cables were also installed along the entire casing and the filter area. The GFZ spin-off FOMON GmbH and the GFZ Section 2.2 “Geophysical Imaging” played a key role in this. The fibre optic cables enable continuous monitoring of the temperature along the borehole at 0.5 metre intervals, as well as the measurement of acoustic signals and strain measurements, which can provide information about mechanical changes in the casing and the borehole cementation. This work was successfully completed in September.

In the current phase, tests are being carried out to extract water from the storage layer, and later also for injection. To this end, the drilling fluid produced during drilling was first removed by clear pumping, whereby the first formation water was already pumped out of the storage layer and sampled. The gradual increase in the pumping rate and the subsequent rest phase provide information about the productivity and hydraulic behaviour of the borehole.

Interim resume

Priv.-Doz. Dr.-Ing. Guido Blöcher, hydrogeologist and head of the “Sustainable Production Technologies” working group in the GFZ Geoenergy Section summarises: “We have determined a promising productivity index of over 1 l/s/bar, which suggests that good production rates can be achieved with the connected sandstone. This is particularly important for large-scale heat storage.”

Stefan Kranz, head of the “Geothermal Process Engineering and System Integration” working group in the GFZ Geoenergy section, emphasises: “The completion of the research borehole now enables further tests to characterise the storage behaviour of the Hettang sandstone. As part of the PUSH-IT project, we will now carry out investigations into the thermal and hydraulic behaviour of the reservoir rock and also look at the influence of temperature on geochemical and microbiological processes.” The results will then be incorporated into the realisation of a heat storage facility for the “Berlin Blockheizkraftwerks- Träger- und Betreibergesellschaft” (BTB).

![[Translate to English:] [Translate to English:] Abror Gafurov von dem Schriftzug "Welcome to Azerbaijan" und den UN und COP Logos](/fileadmin/_processed_/2/5/csm_2024_11_Baku_COP29_Abror_Gafurov_1042faec82.jpeg)

![[Translate to English:] Martin Herold standing in front of the library on the Telegrafenberg](/fileadmin/_processed_/c/d/csm_Martin_Herold_d385ee4dd9.jpeg)

![[Translate to English:] Many people are listening to a presentation in the GFZ lecture hall.](/fileadmin/_processed_/c/a/csm_1_Bild1_hell_b9c0e9f5ed.jpeg)

![[Translate to English:] Both scientists sitting on stools in front of a wall of books in the Telegrafenberg library](/fileadmin/_processed_/6/6/csm_Buiter_Castell_DORA_4_e87cb1ea18.jpeg)

![[Translate to English:] Gruppenbild mit 4 Personen](/fileadmin/_processed_/8/d/csm_20241017_GFZ-Emmerman-Medal-005_web_reinhardtundsommer_21a414fa4a.jpeg)

![[Translate to English:] Ice landscape with five red tents](/fileadmin/_processed_/8/9/csm_Zeltlager_auf_dem_Eis_Urheberin_Jenine_McCutcheon_5ced2d523b.jpeg)