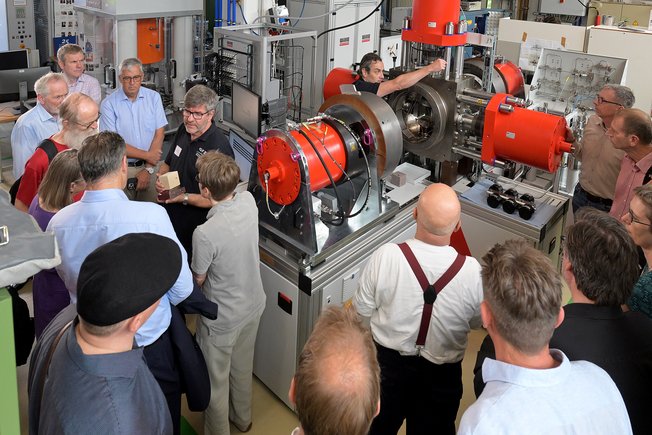

On Friday, 28 June 2024, the new “TrueTriax” high-pressure testing facility for rock samples was inaugurated in the GFZ's high-pressure hall in the presence of guests from politics, industry and science. The new facility can be used to simulate thermal, hydraulic, mechanical and chemical processes at depths of up to ten kilometres. This provides important data for geoenergy research and applications.

Impressions from the inauguration and the TrueTriax-system incl. sample preparation can be seen in the picture gallery above.

Whether deep geothermal energy for regenerative heat supply, heat and cold storage or the geological storage of hydrogen as a future energy source: anyone who wants to use the deep underground for energy must know the processes and interactions that take place there at high pressure and high temperatures between rock and fluids as precisely as possible:

- What is the permeability of the rock for certain fluids or gases? How does this change with varying pressure and temperature?

- Under which loads and from which directions does the rock fracture?

- How does the varying temperature underground influence the fracture properties?

- What chemical reactions take place under these extreme pressure and temperature conditions?

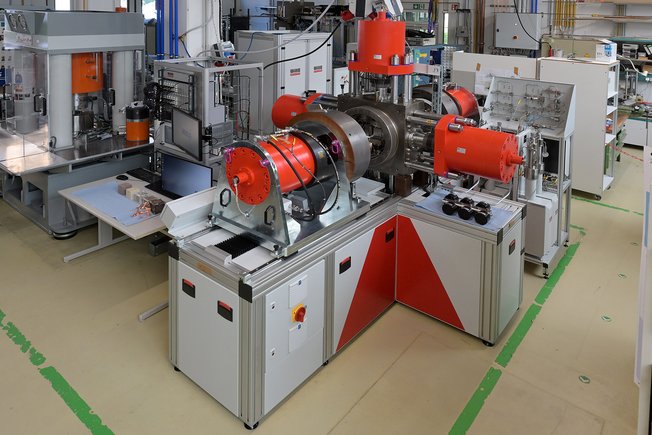

Answers to questions like these will be possible in future with the help of the new reactive, petrophysical high-pressure, high-temperature test facility PAX-1600, known as TrueTriax for short. It allows unique experiments to be carried out under conditions that prevail at depths of up to ten kilometres and are therefore very difficult to access experimentally in nature. In particular, the TrueTriax facility can be used to carry out highly specialised pressure and permeability tests on rock samples, varying and measuring pressure, temperature and flow parameters for gases or liquids. What is special is that these tests can also be carried out with liquids that are similar in composition to deep thermal waters. Acoustic sensors allow the seismic analysis of fracture processes in the rock.

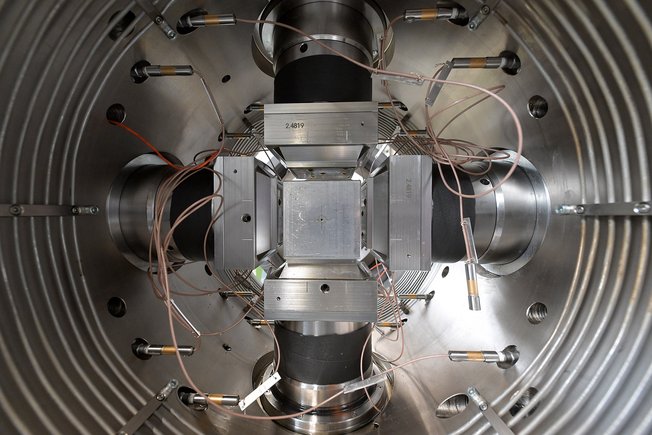

A high-precision grinding system was purchased to prepare the cube-shaped rock samples.

The TrueTriax system was financed by the state of Brandenburg via the Investitionsbank des Landes Brandenburg (ILB) with funds from the European Regional Development Fund (ERDF). In addition to the 1.6 million euros from the EU, the GFZ invested one million euros. The facility was realised by the Göttingen-based company APS Wille Geotechnik according to the specifications of the GFZ scientists

Prof Dr Susanne Buiter, Scientific Director of the GFZ, said at the opening of the inauguration ceremony:

“We would like to thank the state of Brandenburg for its financial support. The TrueTriax facility opens up previously unattainable experimental dimensions for the investigation of important processes in the deep underground. Among our high-calibre infrastructure, this is a forward-looking highlight that will provide us with important new findings in geoenergy research – a field of research that has become particularly relevant to society in recent years. The GFZ is making an important contribution to security of supply and energy independence based on domestic resources. We are available to provide our expertise and independent, fact-based advice and support in response to the increased interest on the part of politicians, industry and the public.”

Prof Dr Ingo Sass, Head of the Geoenergy Section at the GFZ, said:

“We are delighted that we have been able to realise a unique facility with the TrueTriax. The GFZ has thus entered a new field of experimentation worldwide. The facility is our eye into the subsurface: we work with assumptions, models, forecasts – in order to make statements about the subsurface. Measurement data is the indispensable basis for this. The TrueTriax will provide us with unique data on the complex coupled thermal, hydraulic, mechanical and chemical processes.

Last but not least, when drilling for promising reservoirs or storage horizons, it is important to know the conditions in the deep rock as well as possible. Drilling requires investments in the millions, and optimising well planning and forecasts helps to save money: It reduces drilling costs, increases safety and reduces the risk of discovery.”

Efforts for a national triaxial high-pressure press cluster

Following the inauguration of the TrueTriax, a colloquium was held to explore the scientific potential of this type of high-pressure system. In addition to the aforementioned topics of deep geothermal energy, heat and cold storage and hydrogen storage, other fields of application include the final disposal of radioactive waste, the generation of earthquakes and the extraction of critical raw materials such as lithium from geothermal fluids.

There are currently nine similar triaxial facilities at research institutions across Germany, with complementary specialisations. The GFZ is endeavouring to network these into a national triaxial high-pressure press cluster (Triaxial Cell Cluster – TriCC). This will enable the participating universities and non-university research institutions to carry out excellent research on a laboratory scale and open up a wide range of collaborations.

Ingo Sass: “We are also striving for this clustering in order not to lose the scientific and technical lead that we have in Germany and Europe in this field, especially compared to Asia.”

Background: Geoenergy research at the GFZ

The GFZ is home to the largest geoenergy research group in Europe. It combines the scientific and engineering expertise required for the complexity of the topic.

One focus is geothermal energy. Here, the GFZ covers all relevant geothermal systems: hydrothermal, petrothermal and storage systems for cold and heat. And this covers the entire geothermal process chain – from theoretical work to physical-experimental work in the technical centre to operational work on a field scale.

Another focus of geoenergy research is the storage of gases and fluids underground, e.g. CO2. Decades of experience are now to benefit the development of a hydrogen demonstration storage facility.

The transfer of knowledge and technology is particularly important in the field of geoenergy. There are several start-ups at the GFZ that focus on geo-energy, including VFG Lab, fluxTec and to some extent FOMON.

Background: The TrueTriax system

The TrueTriax system was customised to the specifications of the GFZ researchers as a result of around 15 years of research and development work. The manufacturer is the company APS Wille Geotechnik.

With the TrueTriax, rock cubes with an edge length of 80 mm can be pressed from all sides by load stamps. (see picture gallery)

The axial load that can be applied by each of the load stamps is 1600 kN. With a sample size of 80 x 80 x 80 mm³, this corresponds to 250 MPa per surface. This allows rock stresses of up to 10,000 m depth to be simulated.

The sample can be flowed through from all sides at a pore pressure of up to 350 bar. For the simulation of hydraulic stimulation measures, even 600 bar can be achieved. This corresponds to a depth of 3,500 - 6,000 metres. As the entire flow-through system is made of Hastelloy alloy, even highly corrosive fluids can be used here.

A coupled external and internal heating system generates up to 200°C in the chamber and up to 150°C at the sample. This corresponds to the temperatures in the Earth's crust at a depth of approx. 4,500 metres.

During deformation, the fracture behaviour can be acoustically observed, quantified and localised using 24 seismic sensors. This allows the geomechanical rock parameters and the fracture behaviour to be determined with even better quality.

Background: Sample preparation

Rock cubes with an edge length of 80 millimetres are used as samples. The high-precision rock grinding system enables the cube surfaces to be produced with an accuracy of 1/100th of a millimetre. This is necessary for the reproducibility of the test conditions and to ensure an even application of force by the jaws of the press over the entire surface when the cube is pressed together. (See picture gallery)

![[Translate to English:] Group photo with 7 people in front of a new metal plant in a large laboratory hall.](/fileadmin/_processed_/0/4/csm_20240628-GFZ_Einweihung_Triax-Anlage-PRESSE_Abb1_040_c-Bahlo-GFZ_46cdcc5924.jpeg)

![[Translate to English:] [Translate to English:] Abror Gafurov von dem Schriftzug "Welcome to Azerbaijan" und den UN und COP Logos](/fileadmin/_processed_/2/5/csm_2024_11_Baku_COP29_Abror_Gafurov_1042faec82.jpeg)

![[Translate to English:] Martin Herold standing in front of the library on the Telegrafenberg](/fileadmin/_processed_/c/d/csm_Martin_Herold_d385ee4dd9.jpeg)

![[Translate to English:] Many people are listening to a presentation in the GFZ lecture hall.](/fileadmin/_processed_/c/a/csm_1_Bild1_hell_b9c0e9f5ed.jpeg)

![[Translate to English:] Both scientists sitting on stools in front of a wall of books in the Telegrafenberg library](/fileadmin/_processed_/6/6/csm_Buiter_Castell_DORA_4_e87cb1ea18.jpeg)

![[Translate to English:] Gruppenbild mit 4 Personen](/fileadmin/_processed_/8/d/csm_20241017_GFZ-Emmerman-Medal-005_web_reinhardtundsommer_21a414fa4a.jpeg)

![[Translate to English:] Ice landscape with five red tents](/fileadmin/_processed_/8/9/csm_Zeltlager_auf_dem_Eis_Urheberin_Jenine_McCutcheon_5ced2d523b.jpeg)